Solid slag samples

Analysis of solid slags samples

Slag analysis without sample preparation close to the melting process

The highly competitive market for steel and metal production requires continuous improvement.

In many processes, this includes the close control of mostly heterogeneous material feeds and samples for process monitoring.

Unfortunately, most technologies used today for the analysis of heterogeneous materials such as slags require a complex procedure for sample preparation, such as homogenisation of the material to be measured.

Sample homogenisation, which consists of crushing, demetallisation, grinding and finally pressing/melting, takes at least 6 minutes together with XRF analysis, but often more than 15 minutes.

Such long analysis times prevent active slag work based on analysis data, which places tight limits on further process optimisation. Up to now, slags have mostly been analysed for retrospective observation of melts, post-mortem, so to speak. If this "slag pathology" results in deviations from the target value, the melt is already one process step further and can no longer be adequately treated.

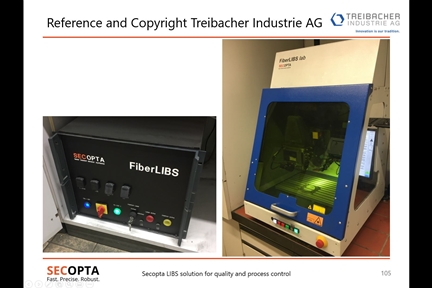

The expensive and time-consuming sample preparation steps can be a thing of the past with a new technology, Laser Induced Breakdown Spectroscopy (LIBS).

But how does it work?

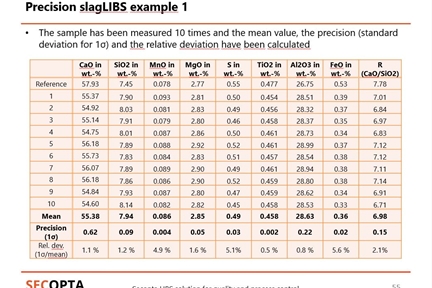

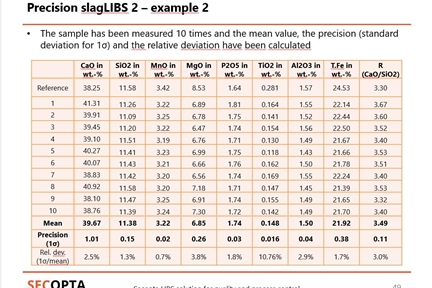

With LIBS and its 1000 measurements per second, homogenisation of data instead of samples is possible.

With the LIBS technology and the analysis in 1-2 minutes, it is now possible to analyse practically in-situ and take measures according to the slag composition as long as the melt is still at the treatment site and within the corresponding parameters (e.g.: temperature).

This not only saves important resources, which leads to more sustainable operation and lower CO2 emissions, but also increases efficiency and process output. And efficiency is a fundamental criterion for success in a highly competitive environment such as the metal industry.

In many processes, this includes the close control of mostly heterogeneous material feeds and samples for process monitoring.

Unfortunately, most technologies used today for the analysis of heterogeneous materials such as slags require a complex procedure for sample preparation, such as homogenisation of the material to be measured.

Sample homogenisation, which consists of crushing, demetallisation, grinding and finally pressing/melting, takes at least 6 minutes together with XRF analysis, but often more than 15 minutes.

Such long analysis times prevent active slag work based on analysis data, which places tight limits on further process optimisation. Up to now, slags have mostly been analysed for retrospective observation of melts, post-mortem, so to speak. If this "slag pathology" results in deviations from the target value, the melt is already one process step further and can no longer be adequately treated.

The expensive and time-consuming sample preparation steps can be a thing of the past with a new technology, Laser Induced Breakdown Spectroscopy (LIBS).

But how does it work?

With LIBS and its 1000 measurements per second, homogenisation of data instead of samples is possible.

With the LIBS technology and the analysis in 1-2 minutes, it is now possible to analyse practically in-situ and take measures according to the slag composition as long as the melt is still at the treatment site and within the corresponding parameters (e.g.: temperature).

This not only saves important resources, which leads to more sustainable operation and lower CO2 emissions, but also increases efficiency and process output. And efficiency is a fundamental criterion for success in a highly competitive environment such as the metal industry.

Customer benefits

- Precise analysis without sample preparation

- Analysis in one step with results in less than a minute

Please contact us for additional information and further application examples.